Debarker Tips for Efficient Log Bark Removal

Top Categories

over 20 years’ experience and professional knowledge, technologically changes our technique, we are dedicated to provides the best Cutting and wear resistance solutions to our valued customers.

-

+86 136 0577 9141

Mon-Fri, 9am until 6pm

-

sales@jyfmachiery.com

We reply within 24 hours

-

Wencheng Economic Development Zone

Wenzhou, China.

Debarker Tips for Efficient Log Bark Removal

A debarker is a machine designed to remove bark from logs before further processing. It plays a critical role in the forestry, sawmill, plywood, pulp, and paper industries. Bark often contains dirt, sand, and stones that can damage cutting tools and negatively affect wood quality. For this reason, bark removal is typically the first step in wood processing.

Debarkers work by applying mechanical force, abrasion, cutting, or impact to separate the bark from the log surface while minimizing damage to the underlying wood.

To achieve optimal performance, selecting the right debarker parts is essential. Worn or improper components can significantly reduce machine efficiency and productivity, while also compromising the quality of the processed logs.

Main Components of a Debarker

A debarker unit typically consists of three main components: the rotating drum, the debarking ring, and the cutter tools. Among these, the cutter tools play the most important role, as they are directly responsible for removing bark from the logs.

Rotating Drum

The rotating drum is where logs are initially fed. As the drum turns, logs rub against one another and against internal ribs, generating friction that loosens the bark.

Debarking Ring

In ring debarkers, a rotating ring equipped with adjustable cutter heads removes bark as logs pass through the center. Feed rollers rotate the log, allowing the cutters to peel bark evenly around the circumference.

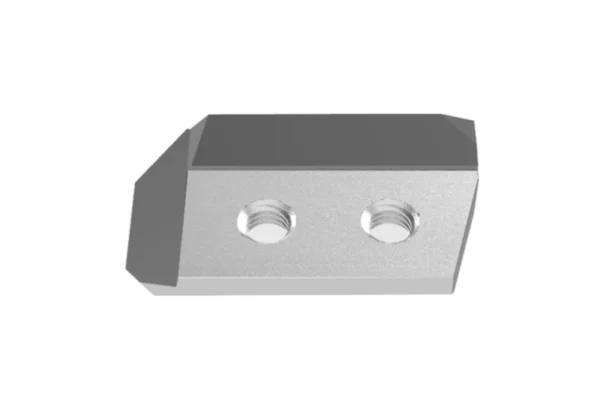

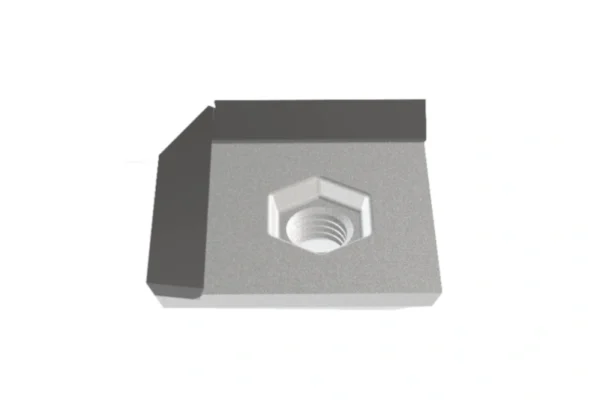

Cutter Heads / Debarker Tips

Debarker tips are the most critical wear parts in the system. They strip bark from the logs and directly affect debarking efficiency, machine uptime, and operating costs.

Because bark may contain sand, stones, and other contaminants, debarker tips are exposed to heavy abrasion, impact, and wear. Poor-quality tips can blunt or break quickly, increasing downtime and replacement costs. For this reason, wear resistance and impact strength are key factors when selecting sawmill debarker tips.

High-Performance Debarker Tips from JYF Machinery

JYF Machinery is a trusted aftermarket manufacturer and supplier of debarker wear parts. We specialize in producing high-performance, durable, and cost-effective alternatives for major debarker brands worldwide.

Our debarker tips are engineered for demanding operating conditions:

- Tip body made from premium alloy steel for strength and durability

- Cutting edges manufactured from dual-grain tungsten carbide for superior wear resistance

- Pressing and sintering processes to enhance impact strength and service life

- Heat-treated and hard-faced surfaces to handle both softwood and hardwood applications

With controlled heat treatment and high-quality materials, our debarker tips deliver clean debarking results and require fewer replacements. In many cases, only occasional sharpening is needed after extended use.

Get High-Performance Debarker Tips from JYF Machinery

JYF Machinery is a professional aftermarket manufacturer of debarker wear parts, delivering reliable, high-performance alternatives to original equipment parts. Using advanced machining technology, experienced specialists, and premium raw materials, we produce debarker tips built for demanding operating conditions.

All products are manufactured under strict quality control to ensure precise fit, durability, and long service life. Trusted by machine owners worldwide, our debarker tips help reduce downtime and lower operating costs.

If you need durable or customized debarker tips for any brand or application, our team is ready to assist. We offer precise manufacturing, responsive support, and worldwide shipping.

Contact JYF Machinery today to request a quote and improve your debarking efficiency.