Flail Mower Blade Hammer – Heavy-Duty Cutting Blades for Tough Vegetation

Top Categories

over 20 years’ experience and professional knowledge, technologically changes our technique, we are dedicated to provides the best Cutting and wear resistance solutions to our valued customers.

-

+86 136 0577 9141

Mon-Fri, 9am until 6pm

-

sales@jyfmachiery.com

We reply within 24 hours

-

Wencheng Economic Development Zone

Wenzhou, China.

- 1

- 2

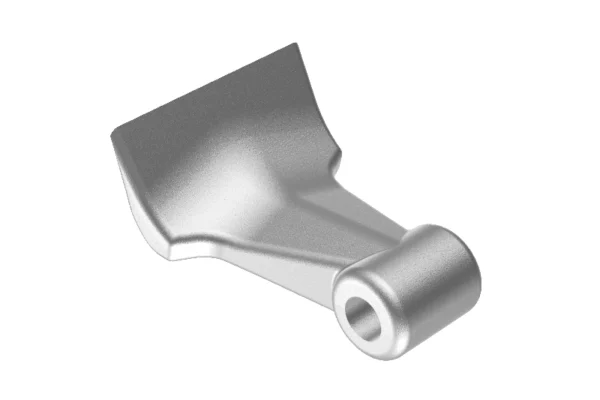

Flail mower blade hammers are engineered for demanding land-clearing and vegetation-management applications. Designed to deliver powerful impact and long-lasting durability, these heavy-duty blades excel at cutting dense grass, brush, and woody material. JYF Machinery flail mower hammer blades are precision-manufactured for reliable performance, reduced wear, and compatibility with a wide range of flail mowers.

Features & Benefits of Flail Mower Hammer Blade

Flail mower hammer blades are designed for heavy-duty cutting applications where strength, durability, and impact resistance are essential. Compared to standard flail blades, hammer blades deliver superior performance in demanding environments such as forestry, roadside maintenance, and land clearing.

Heavy-Duty Construction

Manufactured from high-strength alloy steel and heat-treated for maximum toughness, flail mower hammer blades are built to withstand repeated high-impact cutting.

Excellent Wear Resistance

The thick profile and hardened cutting edges reduce wear, extending service life even when operating in abrasive conditions.

Powerful Cutting Performance

The hammer-style design delivers strong impact force, making it ideal for cutting dense grass, heavy brush, weeds, and woody vegetation.

Stable Operation

Precision manufacturing and balanced weight help minimize vibration, improving cutting efficiency and reducing stress on the mower rotor and bearings.

Wide Compatibility

Designed to fit a variety of flail mower and mulcher models, with multiple sizes and mounting options available.

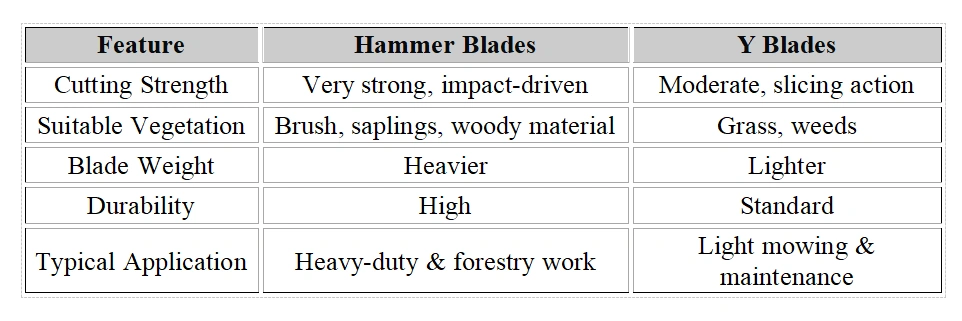

Hammer Blades vs. Y Blades

Selecting the correct blade type has a direct impact on cutting performance, efficiency, and operating cost. The table below highlights the key differences between hammer blades and Y blades to help you select the most suitable option for your application.

Why JYF Machinery Flail Mower Hammer Blades Stand Out

Not all flail mower hammer blades deliver the same level of performance. In demanding operating conditions, low-quality blades can lead to rapid wear, frequent replacements, and reduced productivity. JYF Machinery hammer blades are engineered to outperform standard alternatives, providing reliable cutting power, extended service life, and consistent results in the field.

Advanced Material Engineering

- Manufactured from high-grade alloy steelfor superior strength and toughness

- Heat-treated and tempered to 51–55 HRC, achieving an ideal balance between hardness and impact resistance

- Excellent resistance to wear, deformation, and repeated high-impact loads

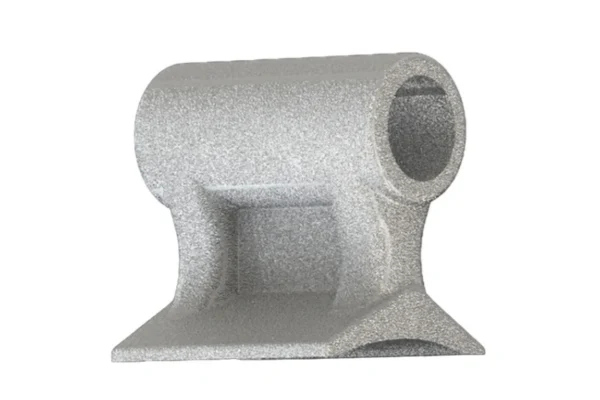

Precision Forging for Superior Durability

- Produced using hot and cold forging processesto optimize internal grain structure

- Forged blades offer greater strength and longevitythan cast or stamped alternatives

- Uniform density and consistent quality ensure reliable performance across every blade

Engineered for Maximum Cutting Efficiency

- Optimized cutting angles improve vegetation processing and cutting effectiveness

- Precisely balanced weight distribution reduces vibration and minimizes stress on the mower rotor

- Designed for easy installation and quick replacement, helping reduce downtime and maintenance costs

How Forging Improves Flail Mower Hammer Blades Performance

Forging is essential to the performance of flail mower hammer blades used in land clearing and vegetation management. It ensures consistent strength, precision, and durability across different blade sizes and equipment types. Below are the key benefits of the forging process.

Aligned Grain Structure

The forging process aligns the metal’s grain structure along the shape of the hammer blade. This alignment improves resistance to wear and impact damage during continuous operation.

Superior Strength

Forged flail mower hammer blades are capable of withstanding demanding land-clearing and vegetation-management conditions without cracking or breaking.

Uniform Density

Forging produces consistent material density throughout the blade, ensuring accurate fitment with equipment components and helping reduce unnecessary wear on mounting systems.

Custom Capability

Forging allows hammer blades to be designed and manufactured in custom shapes and sizes, making it possible to meet specific clearing requirements and equipment configurations.

Forged flail mower hammer blades don’t just survive demanding workloads—they deliver dependable performance and extended service life where durability matters most.

The Bottom Line on Flail Mower Hammer Blades

Quality flail mower hammer blades are the difference between productive vegetation management and expensive frustration. When you invest in properly forged, heat-treated hammer blades for flail mower equipment from JYF MACHINERY, you’re investing in:

- Extended service life that reduces replacement costs

- Superior cutting performance that increases productivity

- Environmental sustainability through efficient mulching

- Reduced equipment wear and maintenance expenses