Tub and Horizontal Grinder Wear Parts

Top Categories

over 20 years’ experience and professional knowledge, technologically changes our technique, we are dedicated to provides the best Cutting and wear resistance solutions to our valued customers.

-

+86 136 0577 9141

Mon-Fri, 9am until 6pm

-

sales@jyfmachiery.com

We reply within 24 hours

-

Wencheng Economic Development Zone

Wenzhou, China.

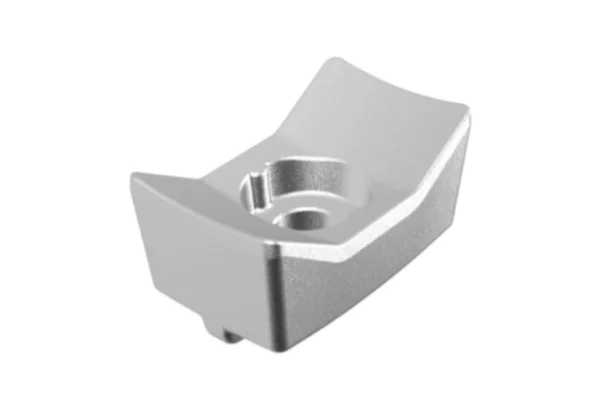

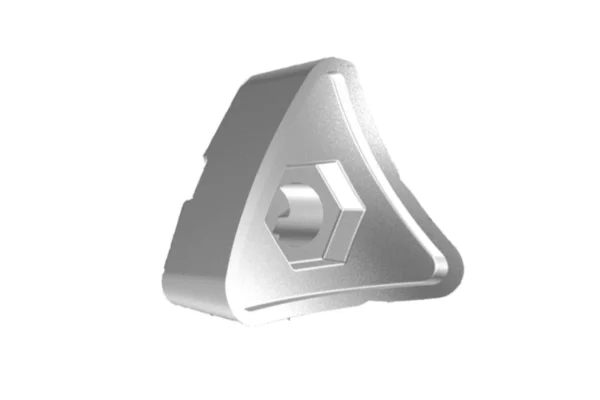

Types of Tub and Horizontal Grinder Tips

Types of Hammermill Hammers

- 1

- 2

What are Tub and Horizontal Grinder Wear Parts?

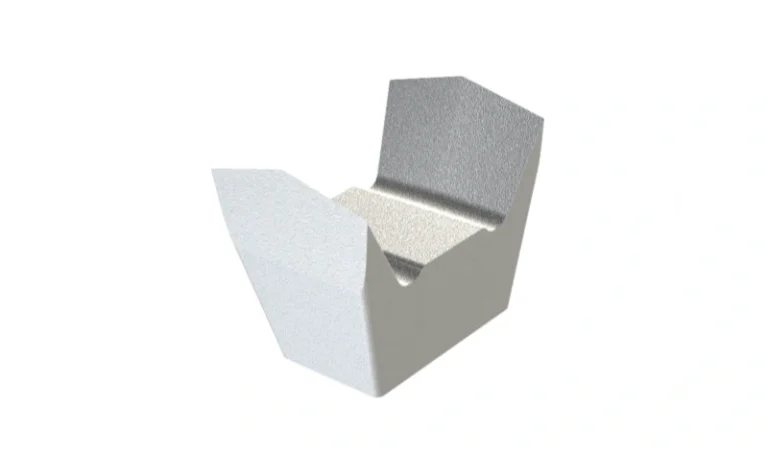

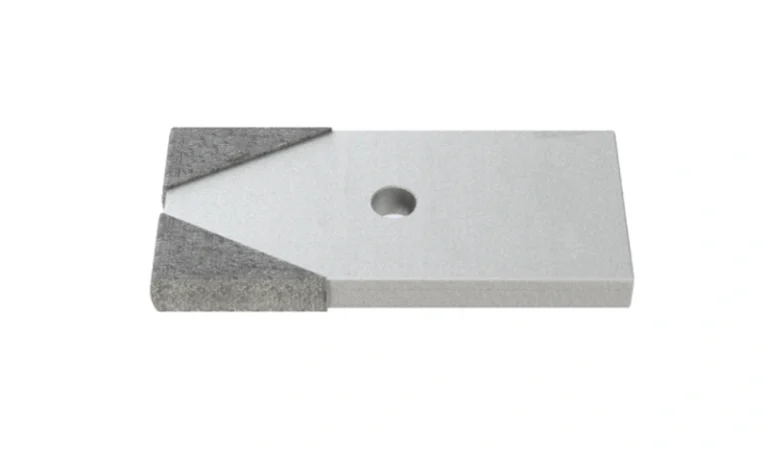

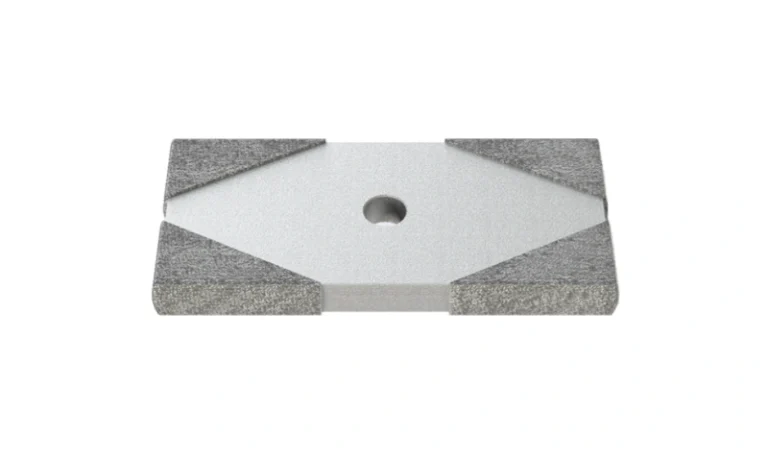

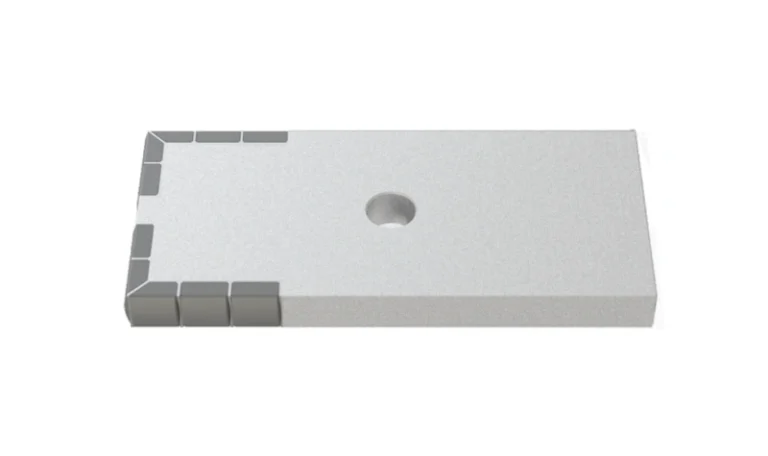

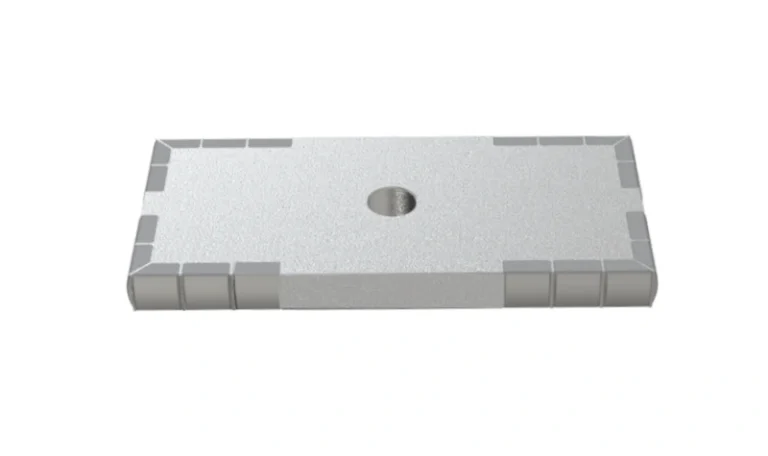

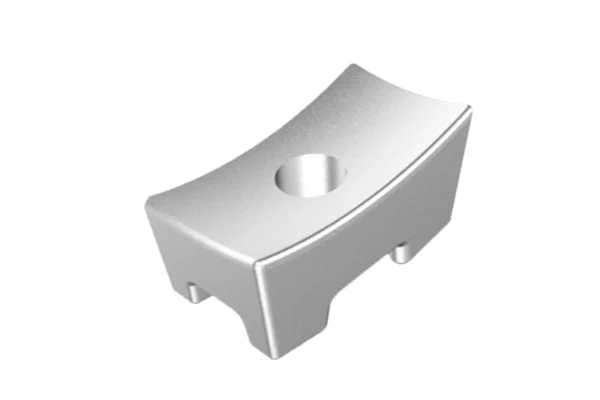

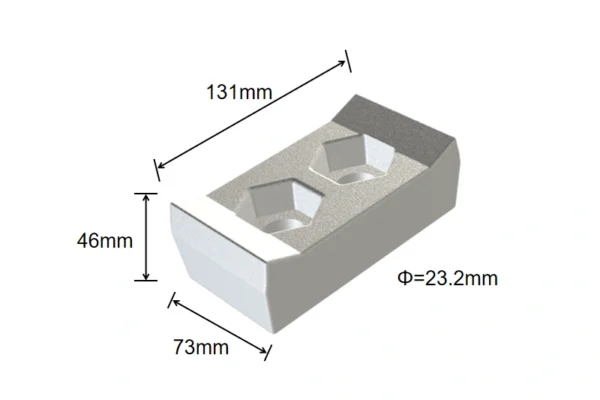

Tub and Horizontal grinder wear parts are replaceable components used in the grinding of wood materials, including trees, branches, and logs. These parts include grinder tips, carbide teeth, tub grinder hammer, blades, anvils, cutters, screens, and holder. These parts are essential in maintaining the optimal performance of shredders and grinders, which are commonly used in the forestry, landscaping, and wood processing industries.

Applicable Brands and Equipment

JYF Machinery provides cost-effective solutions tailored for customers to keep their waste treatment and biomass business running normally. We manufacture various types of grinder wear parts for tub grinders and horizontal grinders etc,These wear parts for tub and horizontal Grinders are manufactured from high-quality materials such as carbide, steel, and other alloys to ensure durability, strength, and longevity. that are suitable for the following brands of waste disposal equipment. such as CBI, Morbark, Diamond Z, Peterson, Vermeer and more. Note that the products listed on the website are only our selected products. Please contact us if you can’t find the product you want on the website!

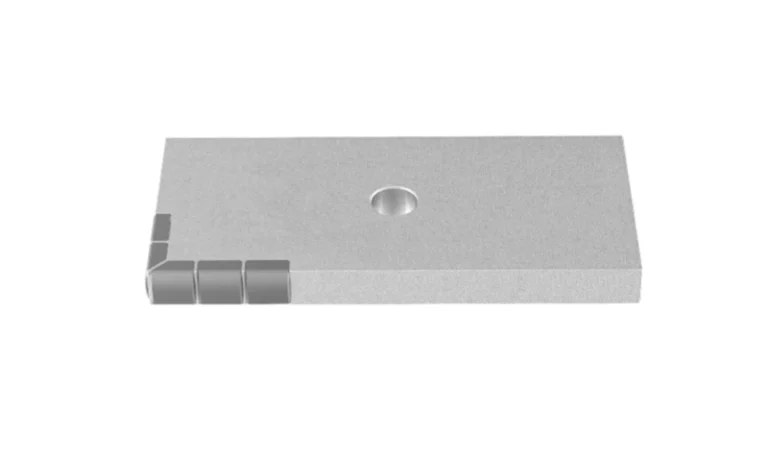

Forging Process for Manufacturing Grinder Wear Parts

At JYF Machinery, we use the latest forging technology to produce high-quality grinder wear parts that exceed our customers’ expectations. Our experienced engineers and technicians work closely with our customers to understand their unique needs and requirements and design wear parts that meet or exceed their specifications.

- At JYF Machinery, we understand the diverse requirements of our customers when it comes to processing different materials. That’s why we offer the flexibility to adjust tool designs, cutting methods, material composition, hardness, impact toughness, and strength based on your specific needs. Our goal is to provide customized tools that address your pain points and ensure seamless production for your operations. For more detailed information and personalized assistance, please don’t hesitate to get in touch with us. We are here to cater to your unique requirements and deliver tailored solutions.