Shredder Blades & Shredder Wear Parts

Top Categories

over 20 years’ experience and professional knowledge, technologically changes our technique, we are dedicated to provides the best Cutting and wear resistance solutions to our valued customers.

-

+86 136 0577 9141

Mon-Fri, 9am until 6pm

-

sales@jyfmachiery.com

We reply within 24 hours

-

Wencheng Economic Development Zone

Wenzhou, China.

Explore JYF Machinery’s precision‑engineered Shredder Blades & Shredder Wear Parts — rugged, high‑performance components crafted from premium alloy and wear‑resistant materials to keep your industrial shredders, grinders, and recycling equipment running with maximum efficiency and minimal downtime.

Shredder: Efficient Waste Management

Shredder utilizes cutting, tearing, and squeezing actions between blades to effectively crush solid waste, reducing its size for subsequent screening and sorting. The versatile machine finds extensive applications in the processing of various materials such as waste plastics, rubber, wood, electronic waste, and other bulky waste items. By employing shredders, solid waste materials can be efficiently managed and prepared for further recycling or disposal..

Premium Features of JYF Shredders for Superior Performance

JYF Shredders are built to deliver efficiency, durability, and versatility, making them the ideal choice for handling a wide range of industrial and municipal waste materials. Here are some key features that make JYF Shredders stand out:

Wide Material Compatibility

Efficiently handles bulky materials such as pipes, metal barrels, tires, wood, plastic films, and large rolls, serving diverse industrial applications.

Precision-Engineered Frame

The sturdy combined-structure frame and large-diameter input hopper allow safe and smooth feeding of oversized materials..

Powerful Rotating Shaft

Equipped with a high-strength, large-angle hexagonal column, providing consistent torque and cutting force for tough materials.

Advanced Rotary Knife Design

Customizable blade thickness, shape, and arrangement deliver superior shearing power, sharp cutting edges, and efficient material reduction.

Low-Speed, Low-Noise Operation

Optimized to reduce noise and dust while minimizing wear on both the machine and environment.

Durable Alloy Steel Blades

High-strength, wear-resistant alloy steel knives ensure long service life and consistent shredding performance.

These features combine to maximize productivity, minimize downtime, and provide reliable waste processing solutions across a variety of industries.

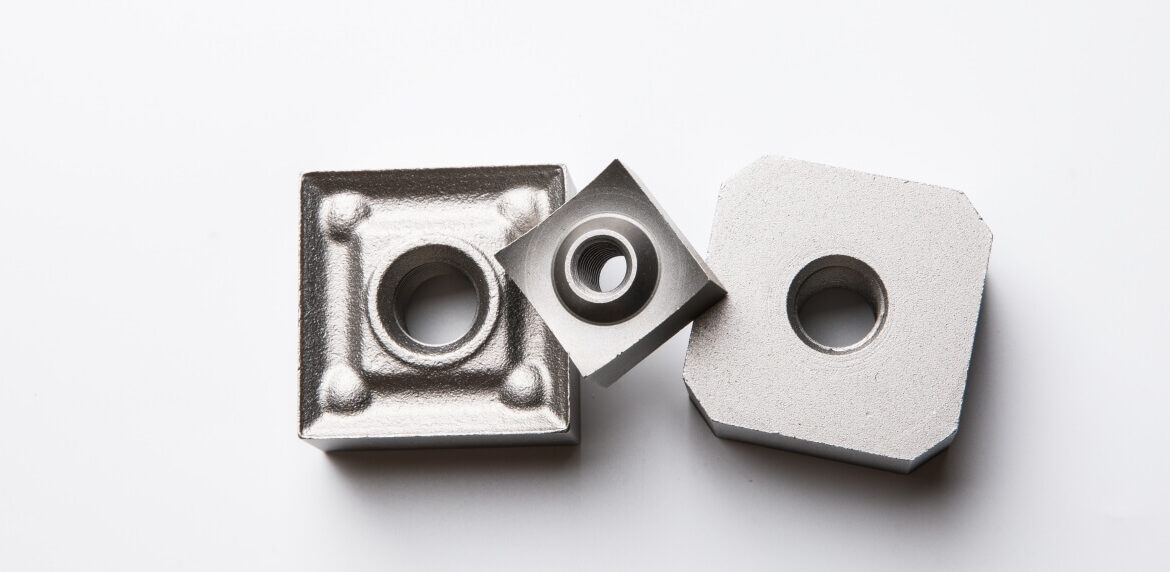

Shredder Blade Types

JYF Machinery offers a wide range of shredder blades designed to meet the diverse needs of different shredding applications. Each blade type is engineered for specific materials and processing requirements, ensuring optimal efficiency and performance.

- Single Blade:Ideal for light or general shredding tasks, providing reliable performance for softer or less dense materials.

- Double Blade:Features two rotating blades for higher shredding efficiency and finer cutting results, suitable for more demanding operations.

- Hook Blade:Designed with a hooked end to handle fibrous materials, paper, and fabric, ensuring smooth feeding and consistent shredding.

- Needle Blade:Slender, needle-like design for processing soft and fluffy materials such as textiles, sponges, and foam.

- Shear Blade:Two cooperating blades used to shear harder materials including metals, plastics, and rubber, delivering precise and powerful cutting action.

- Dual Shaft Blade:Optimized for dual-shaft shredders, offering higher processing capacity and improved material decomposition.

- Fan Blade:Commonly used in pellet machines and pellet shredders for achieving finer particle processing.

With these versatile options, JYF shredder blades provide customized solutions for any material, ensuring maximum efficiency and reliability in industrial shredding operations.

Versatile Shredder Blades for Diverse Applications

JYF Machinery provides high-quality, versatile shredder blades designed to handle a wide variety of materials and shredding needs. Each blade is carefully engineered to ensure efficient, reliable, and consistent performance, helping businesses improve productivity and reduce downtime.

Common Applications:

Wood and PE pipes

Perfect for recycling and size reduction.

Plastic bottles, films, and woven bags

Smoothly processes flexible and lightweight materials.

Copper wires and circuit boards

Efficiently handles electronic waste.

Metals and household appliances

Durable blades designed for tough, dense materials.

Medical waste and vehicle recycling

Safe and precise shredding of complex or sensitive materials.

Reliable Shredder Blades & Wear Parts for Maximum Performance

At JYF Machinery, we are committed to providing high-quality shredder blades and wear parts that deliver exceptional durability, precision, and performance. Our products are engineered to withstand the toughest shredding conditions, ensuring your machines operate efficiently and reliably.

Whether you need standard or customized blades and knives, we can tailor the design, material, and hardness to meet your specific shredding requirements. Maximize your productivity, reduce downtime, and protect your investment with JYF’s precision-engineered solutions.

Get in Touch Today to discuss your needs, request a quote, or learn more about how our shredder blades and wear parts can optimize your operations.